Filling systems in vintage fountain pens

Step through fountain pen history as we explore filling systems that are found in vintage fountain pens.

Ever since an inspired person found that a quill was hollow and could hold a bit of ink, people have tried to create their own, man-made version with a reservoir in order to avoid constantly dipping a pen in the inkwell. With the fountain pen, we finally succeeded. Throughout the 1800s and into the mid-1900s there were innovations that produced different filling systems. Today I will talk about them.

Eyedropper

The first-ever fountain pen filling system is operated by directly placing ink into the barrel using an eyedropper. The earliest attempts weren't very reliable writers because the air exchange was terrible. To try to remedy this, companies made these pens with two feeds, one above the nib and one below. A little later, companies began production of safety pens. A safety pen is an eyedropper-filled pen in which the nib unit retracts into the barrel by twisting the knob at the end of the barrel or with a push-pull action. That innovation made pens more reliable writers, because the feed is always saturated with ink and ready to write.

Around late 1920s and early 1930s, to prevent ink burping, Japanese manufacturers began adding a shutoff valve to their pens. These pens are known as Japanese eyedroppers. This variant of the eyedropper system has a rod going through the body of the pen with a rubber gasket seated at the end of the rod. The gasket comes in contact with the lower reservoir and nib unit. By screwing in or unscrewing the end of the barrel, one may close and open the ink flow, limiting the amount of air that can expand to create excess ink flow.

Ink sac with pressure bar

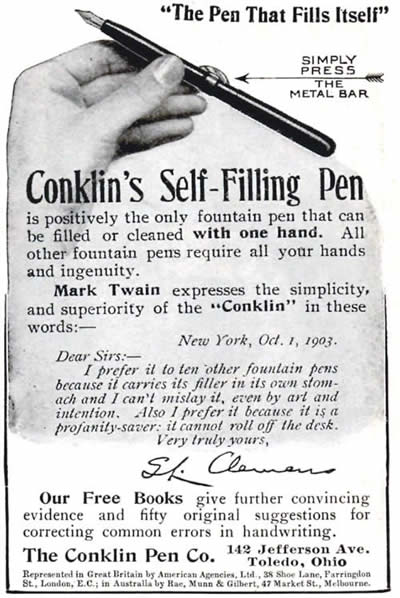

In the early 1900s, companies started producing fountain pens with built-in filling systems consisting of a metal pressure bar and a latex sac inside the barrel. By pressing and releasing the pressure bar, the sac would compress, and then take in ink as the sac expanded again, creating negative pressure. One of the first pens to be filled using this method came out in 1901, the Conklin Crescent Filler. Embedded in the barrel is a rotating ebonite locking ring, and sitting directly above is a brass ring that serves to actuate the pressure bar. The locking ring serves as a safety measure to make sure you don't accidentally expel the ink by pressing on the brass ring.

With this pen came another first—the very first advertisement in the U.S. that featured a celebrity endorsement:

In 1905 Walker & Davison patented the first button filler. However, it wasn't mass produced until the patent expired 7 years later, and Parker started manufacturing the Parker Duofold. The pressure bar in these pens is activated by pressing a button at the end of the barrel.

In 1907 Sheaffer produced the first lever filler. The lever was attached to the side of the barrel and attached to the pressure bar. Levers were made mostly out of steel with either nickel or gold plating. Some manufacturers like England's Mabie Todd & Co. made them out of ebonite.

English company Mabie Todd & Co. introduced another variant, the leverless system. To actuate the pressure bar, one pushes the knurled end of the barrel to the left and then twist it to the right to let the sac expand.

Vacuum filler

In 1932 Parker began testing a new pen with a vacuum filling system called the Golden Arrow. When Parker began manufacturing them in 1933, the name was changed to Vacumatic.

A latex diaphragm had a pellet inside the sac that was pushed into an ebonite retainer strip. The diaphragm was thus folded onto itself. By pressing and releasing the plunger, the diaphragm would slide up and down inside the barrel creating and then releasing vacuum, sucking up ink. Due to this mechanism's small footprint, even the smallest versions of this model have a big ink capacity.

Syringe filler

Pens using a syringe filling system are the most difficult to find. They first show up in the mid-1800s. If you’re looking to restore pens from that era, you most likely would need to make your own parts for the filling system.

In the early 1930s, London's Wyvern company created Ford's "Patent Pen". (There are mentions of Valentine and De La Rue companies as manufacturers.) This pen is arguably the best engineered pen of that period—and some might even describe this pen as over-engineered. You can watch the complex design of this filling system in the video below.

Piston filler

Even though the first patent for a piston filling system was filed in the 1800s, the first piston-filling pen didn't come out until 1929. Pelikan bought the patent from Hungarian engineer Theodor Kovacs and simply called it "The Transparent Pelikan Fountain Pen". These pens utilized a telescopic piston mechanism. After minor changes, this pen was introduced as the Pelikan 100. This system with very few changes is still used on flagship Pelikan pens to this day.

Touchdown filler

Sheaffer introduced their touchdown filling system in 1949. This pneumatic filling system replaced their vacumatic line of pens. This filling system did not have as big of an ink capacity as vacuum filling pens, but it was advertised that it was refillable with just a single stroke.

In 1952 Sheaffer added a snorkel to this design. By this point, ballpoint pens were beginning to dominate the market and the premise that you don't need to wipe the ink from the grip section after filling this pen was very appealing.

Conclusion

As you can see, from the 1800s into the mid-1900s, innovations in fountain pens were aplenty. The great variety of filling systems gives us insights into the evolution of fountain pens and writing tools in general.

You can also read Toga's post to explore filling systems in modern fountain pens.

If you have any questions, you can reach out to me on Mastodon.